Experience the Excellence

By seamlessly integrating proactive and reactive maintenance strategies into our operations, we ensure that the tools are always operating optimally. Combined with our extensive capabilities, including CNC machining and other advanced technologies, PLASTICUM maximizes tool performance and longevity, enabling us to provide consistent, high-quality injection-molded components to meet our clients’ exact specifications and industry demands.

Empowering Plastic Transformation

The pursuit of precision is an ongoing journey. We constantly analyze data, gather insights, and make iterative refinements in our processes. These refinements are aimed at enhancing the precision of the tools, minimizing variability, and elevating the overall quality of injection-molded products.

Sculpting Innovation

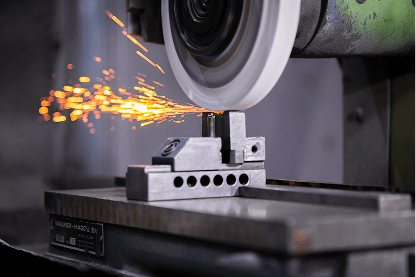

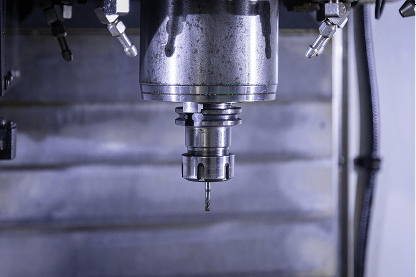

Precision begins at the machining stage. We employ cutting-edge technologies, including CNC machining, EDM, and high-precision milling. These technologies enable us to craft tooling components with incredibly tight tolerances, achieving the exact specifications required for the injection molding process.

Crafting Dreams Together

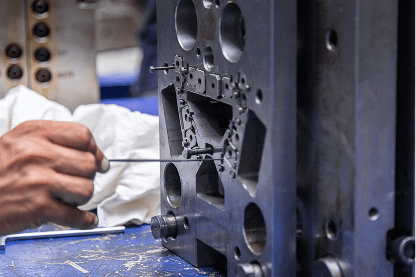

At the heart of precision is excellent engineering. Our team of skilled engineers leverages their expertise and experience to meticulously design tooling that aligns with the project’s requirements. This includes assessing tolerances, material properties, and anticipated stress points to ensure the tool is designed for longevity and optimal performance.

Industry-leading Tools

Our capabilities, including CNC machining, EDM (Electrical Discharge Machining), and advanced milling, are vital in tool maintenance and fabrication. CNC machining ensures precise and consistent tooling components. EDM is utilized for complex shapes and intricate details. Additionally, milling helps in tool modification and enhancement, contributing to extended tool life and improved performance.

Experience the Excellence

Our integrated tool management covers every stage — from design to maintenance — ensuring tool durability, production efficiency, and consistent quality.

Total Mold Lifecycle Management

BENEFITS

3-axis high-precision machining for mold base preparation and core/cavity work

Ideal for flat and moderately contoured surfaces

Supports hard steel and aluminum tool components

FEATURES

Reliable dimensional accuracy for mold parts

Enhances consistency in repetitive operations

Forms the foundation for robust, long-lasting molds

BENEFITS

Fine, non-contact welding for micro-repairs and modifications on tooling

High focus precision with minimal thermal distortion

Suitable for tight areas and complex geometries

FEATURES

Extends the life of expensive mold components

Reduces downtime during maintenance

Allows precise correction without disassembling the tool

BENEFITS

Electro-Discharge Machining for hard metals and fine tolerances

Wire cutting enables extremely precise cuts and internal features

No mechanical contact = stress-free machining

FEATURES

Enables complex shapes and undercuts that standard CNC can’t handle

Delivers tight tolerances essential for mold sealing surfaces

Increases tool quality, reducing cycle time issues in molding

BENEFITS

High-frequency sound waves to clean molds with precision

Reaches micro-cavities and tight mold sections

Uses non-abrasive cleaning liquid

FEATURES

Removes residue without damaging mold surfaces

Ensures consistent part quality by maintaining clean tool cavities

Extends mold service life with regular, gentle cleaning

BENEFITS

Dry ice blasting technology to clean molds without water or chemicals

Non-abrasive, non-conductive, and eco-friendly

Fast and safe for in-place cleaning

FEATURES

Minimizes mold maintenance time

No drying or reassembly needed = reduced downtime

Perfect for maintaining molds in production without heat distortion

BENEFITS

Enclosed cleaning unit (typically using filtration and airflow systems)

Designed to eliminate dust and airborne contaminants

Supports maintenance and inspection under controlled conditions

FEATURES

Protects critical mold components from contamination during handling

Maintains ISO-level cleanliness in tool preparation areas

Supports your quality assurance and traceability efforts

Applications & Use Cases

Durable tooling. Controlled performance. Zero compromise. At PLASTICUM, our commitment to precision doesn’t end at mold delivery. We actively manage each tool from its first shot to end-of-life, ensuring full visibility, preventive actions, and production continuity across programs and locations.

- Automotive Series Production

- Long Lifecycle Industrial Programs

- Complex Multi-Cavity Molds

- Critical Regulatory Markets