BUILT FOR MOTION

At PLASTICUM, our commitment to the automotive sector stems from a deep understanding of its pace, pressures, and uncompromising standards. More than just a supplier, we act as a manufacturing partner, delivering precision-engineered plastic parts that meet global compliance requirements and customer expectations. From interior aesthetics to functional safety components, we help shape the vehicles of tomorrow through lean, scalable, and quality-driven injection molding solutions. Our close relationships with OEMs and Tier 1 suppliers reflect a shared ambition: improving performance, reliability, and design across every vehicle platform.

DEDICATED TO INNOVATION

At Plasticum, innovation is not an afterthought — it’s engineered into every stage of our process. Across all industries we serve and every capability we master, our teams apply advanced technical know-how, cutting-edge tools, and a proactive mindset to help clients meet complex design, cost, and sustainability challenges. From high-performance engineering polymers to optimized mold designs and precision injection technologies, our aim is to co-create smarter, lighter, more efficient solutions. We partner early and think long-term — because true innovation isn’t just about making things — it’s about making things better, faster, and cleaner.

IATF 16949 CERTIFIED

PLASTICUM is IATF certified, reflecting our commitment to the highest quality standards in the automotive industry. This certification ensures our processes — from design to manufacturing — meet strict industry requirements.

Interior components

In the interior of a vehicle, aesthetics, comfort, and functionality are paramount. We manufacture a wide range of injection-molded interior components, including dashboards, door panels, seat components, and trims. These components are designed to enhance the driver and passenger experience while ensuring durability and attractive aesthetics.

exterior components

Exterior components demand precision and resilience to withstand various environmental conditions. Our injection-molded exterior parts, such as bumpers, grilles, body panels, and mirror housings, are crafted to provide not only structural integrity but also aesthetic appeal. We strive to contribute to the overall design and aerodynamics of the vehicle.

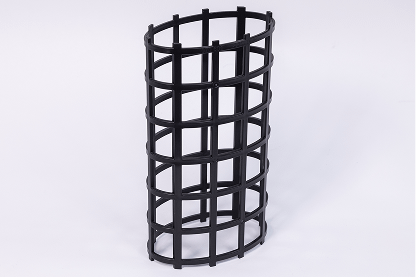

Engine & Under-the-Hood Parts

In the engine and under-the-hood areas, performance, heat resistance, and durability are critical. We produce a range of components such as air intake manifolds, engine covers, and cooling system parts using advanced materials and techniques. These components are designed to withstand high temperatures and maintain optimal functionality.

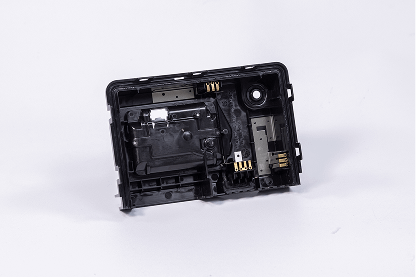

Electrical & Electronic Systems

Modern vehicles incorporate a multitude of electrical and electronic systems. Our injection-molded parts include connectors, brackets, and enclosures for these systems. We ensure precise manufacturing to meet the industry’s stringent electrical and safety standards.

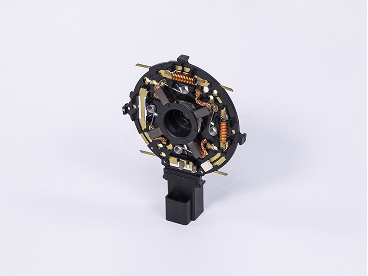

Safety

& Functional Parts

Safety is a paramount concern in the automotive industry. We manufacture critical safety components such as airbag housings, seat belt parts, and sensor enclosures, ensuring they meet rigorous safety standards and contribute to the overall safety of the vehicle.