Powering Precision Systems

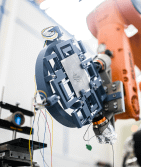

Mechatronics sits at the intersection of mechanical performance, precision electronics, and functional integration — a perfect match for our injection molding expertise. At PLASTICUM, we support manufacturers of sensors, actuators, drive systems and robotic assemblies with robust plastic parts engineered for tight tolerances, repeatability, and compatibility with hybrid assemblies. Whether for automation, smart mobility, or industrial machinery, we are a reliable partner for delivering lightweight, form-locked, and high-performance plastic parts that enable smarter, more connected systems.

DEDICATED TO INNOVATION

At Plasticum, innovation is not an afterthought — it’s engineered into every stage of our process. Across all industries we serve and every capability we master, our teams apply advanced technical know-how, cutting-edge tools, and a proactive mindset to help clients meet complex design, cost, and sustainability challenges. From high-performance engineering polymers to optimized mold designs and precision injection technologies, our aim is to co-create smarter, lighter, more efficient solutions. We partner early and think long-term — because true innovation isn’t just about making things — it’s about making things better, faster, and cleaner.

Multi-Material Expertise

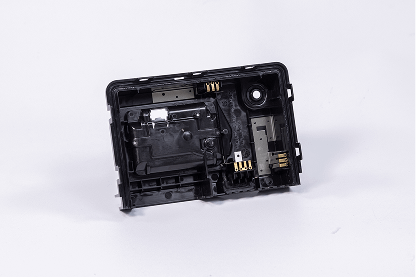

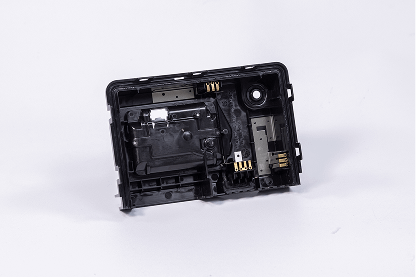

We manufacture precision parts that integrate mechanical function with electrical components, including gear housings, sensor supports, and switch modules.

Tight Tolerances for Complex Assemblies

Our high-precision machines deliver components with micron-level accuracy. This ensures reliable assembly and optimal performance in mechatronic systems.

Integration-Ready Design

We co-develop parts for plug-and-play assembly in robotic, automotive, or automation systems. This reduces client-side rework and assembly errors.

Resistant Technical Polymers

Parts are molded using engineered plastics like PBT, PA66, and others suited for friction, heat, or vibration—common in mechatronic environments.

Smart Manufacturing

We use real-time quality control, cavity traceability, and predictive maintenance systems to ensure zero-defect delivery and full production transparency.

Enabling Innovation

From servo drives to actuator systems, our components power the evolution of motion control and automation in multiple industrial sectors.