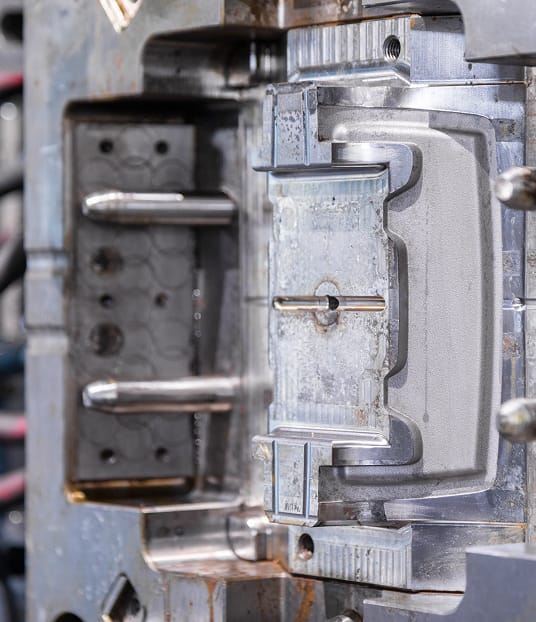

Custom Mold Design

Our team of experienced engineers meticulously designs molds that align with your project’s specifications. We consider factors such as part geometry, material flow, and cooling strategies to optimize mold performance.

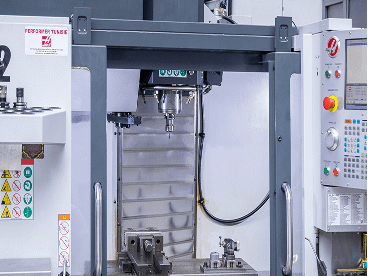

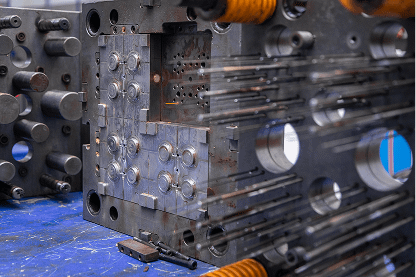

Precision CNC Machining

Craftsmanship is at the heart of our mold manufacturing process. We utilize state-of-the-art CNC machining equipment and techniques to ensure the highest level of precision.

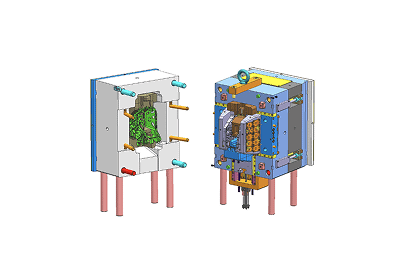

Multi-Cavity Molds

For projects that demand high-volume production, our multi-cavity molds offer an efficient solution. They allow for the simultaneous production of multiple parts, reducing cycle times and costs.

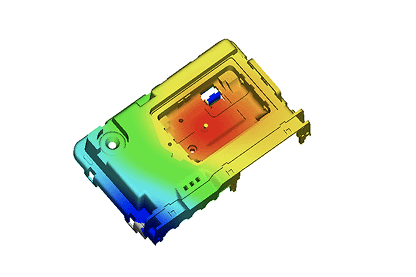

Mold Flow Analysis

Mold Flow Analysis allows us to detect issues like air traps, weld lines, or uneven filling early on. It helps optimize design and choose the right material by evaluating properties like viscosity and melt temperature for a smooth injection process.

Quality Assurance

Throughout the tooling manufacturing process, we maintain rigorous quality control measures. Our quality assurance team conducts thorough inspections and tests to ensure that every mold meets our exacting standards.

Maintenance and Refurbishment

We understand that tooling requires ongoing care to maintain peak performance. We offer maintenance and refurbishment services to extend the lifespan of your molds and reduce long-term costs.

Industrial-Grade Tooling

FEATURES

Reduces tool count

Lowers total part cost

Simplifies production planning

BENEFITS

Multiple part geometries per tool

Balanced runner systems

Optimized ejection

FEATURES

Etched or polished cavity surfaces

VDI 3400 / SPI finish standards

Compatible with painting or visible parts

BENEFITS

Eliminates secondary finishing

Enhances product look & feel

Ensures brand consistency

FEATURES

Premium mold steels (H13, 1.2343, etc.)

Enhanced cooling circuits

Anti-corrosion coating

BENEFITS

Maximizes ROI over time

Reliable for high-volume programs

Less downtime and tool changeover

FEATURES

Side-action slides

Removable core inserts

Hydraulic/pneumatic actuation

BENEFITS

Enables undercuts or complex parts

Easy core exchange

Simplifies mold maintenance

FEATURES

Standardized baseplates (HASCO/DME)

International cooling/heating connectors

Local documentation & protocols

BENEFITS

Deployable in third-party factories

Smooth international transfer

Full interoperability with client machines

mold grades

Whether for high-volume consumer components or complex multi-material technical parts, our mold grades and engineering resources are built to meet demanding international standards for performance, durability, and consistency.

- High-Precision Hardened Steel

- Multi-Cavity Family Molds

- Complex Geometrical Molds

- Grained & Textured Molds

- Soft Tools / Pilot Molds

- Export-Grade Molds