Collaborative Design Workshops

Our engineers work closely with your team to brainstorm ideas, refine concepts, and ensure that every detail is considered. We encourage open dialogue, brainstorming, and the exploration of multiple design concepts to find the best solutions. Your input is central to the workshop process.

Design for Manufacturability (DFM)

We conduct thorough DFM assessments to identify potential issues and streamline the manufacturing process. By addressing these challenges early, we streamline the manufacturing process, resulting in faster turnaround times With DFM, we can quickly iterate and refine prototypes, reducing development time and allowing for faster product launches.

From Concepts to Prototypes

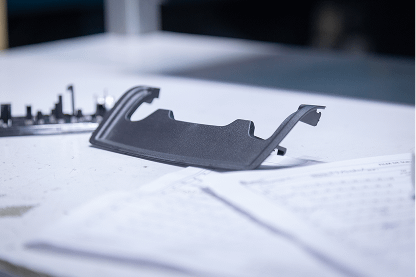

Prototypes are the bridge between concept and production. We create physical prototypes that allow you to see, touch, and test your design. This hands-on approach is invaluable for refining and validating your concept.

Iterative Improvement

Prototyping often leads to insights and improvements. We iterate and refine the design based on your feedback, ensuring that the final product aligns perfectly with your vision and objectives.

Material Selection Guidance

Choosing the right material is critical. We help you choose the most suitable materials for your project, considering factors such as strength, durability, cost, and environmental impact. Our commitment to sustainability means that we prioritize eco-friendly materials whenever possible.

Turn your vision into a manufacturable reality

Throughout the entire co-design and development journey, you can expect open communication, transparency, and a relentless pursuit of excellence. We’re not just in the business of making products; we’re in the business of bringing your visions to life.

From Concept to Precision

FEATURES

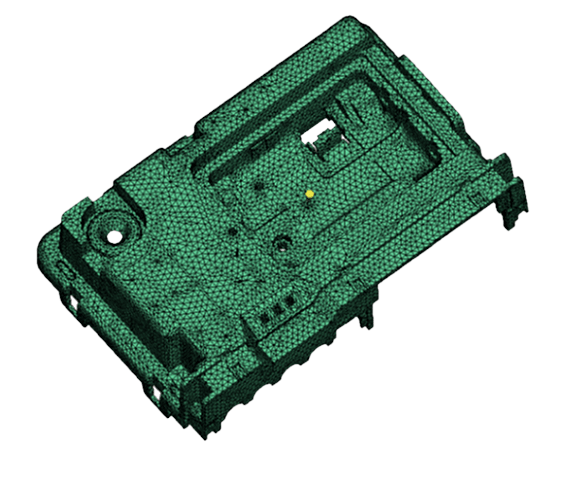

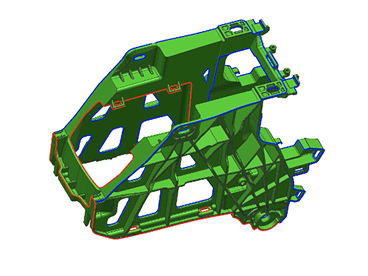

Advanced 3D CAD modeling for surfaces, solids, and assemblies

Integrated parametric and direct modeling capabilities

Seamless integration with PLM systems for version control

BENEFITS

Accelerates the design-to-tooling transition by ensuring precision from concept to mold

Enables quick modifications and design iterations through parametric control

Improves collaboration between design, tooling, and production teams

FEATURES

Simulation of flow behavior, stress distribution, and material deformation

Compatibility with multiple material databases and real-world constraints

Visual heatmaps and reports for part/mold optimization

BENEFITS

Minimizes risk of defects (e.g., warpage, sink marks, flow hesitation) before tooling

Reduces material usage and improves structural integrity of final part

Supports confident decision-making during DFM and co-engineering phases

FEATURES

Simulates resin flow, cooling, weld lines, and air traps inside the mold cavity

Allows virtual testing of gating systems, runner balance, and venting zones

Integrated with CATIA and other CAD platforms for direct data import/export

BENEFITS

Optimizes part design and mold layout before steel cutting

Increases first-shot success rate and reduces mold trial iterations

Saves costs by preventing tool rework and reducing ramp-up scrap

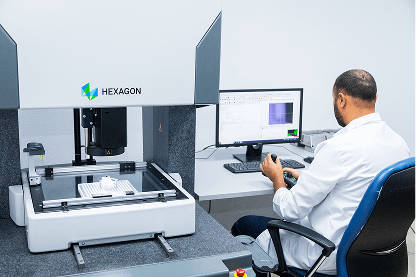

FEATURES

All parts are produced precisely to client-supplied 2D/3D drawings and tolerances.

Materials, injection parameters, and surface finishes are applied according to the client’s technical data sheets and specs.

Full DHR (Device History Record) and batch traceability available for all production runs, with inspection reports upon request.

BENEFITS

Clients retain full ownership of the design with no alteration, ensuring IP protection and regulatory alignment.

By eliminating the co-design loop, the process moves straight into mold validation and series production.

B-to-P is especially suited for validated parts already in market or undergoing transfer tooling to reduce sourcing risk.

Applications TYPES

We support product development across a broad spectrum of polymers and technical applications, each selected for its performance, processing behavior, and final use conditions.

- Connectors & Insulators

- Consumer Interfaces

- Technical Enclosures

- Fluid & Air Handling

- Structural Supports

- Sealing & Overmolding Zones

- Interior Trim & Control Parts