Comprehensive Solutions

Imagine a product that begins as a vision, takes shape through precision injection molding with meticulous care. But it doesn’t stop there. Our commitment to delivering comprehensive solutions shines when we add the finishing touches.

Component Assembly

When your project involves multiple parts that need to come together seamlessly, we offer component assembly services. Our skilled technicians ensure that each component is fitted and secured correctly, resulting in a finished product ready for use.

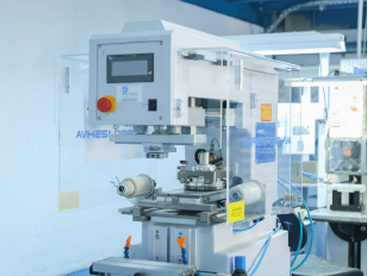

Laser & Pad Printing

Our advanced capabilities include laser and pad printing, which allow us to add intricate designs, branding, and labeling to your plastic components. Laser printing offers precision engraving, ensuring durability and clarity of markings. On the other hand, pad printing allows us to transfer detailed graphics onto irregular or contoured surfaces with unmatched precision and vibrancy

Streamlined Supply Chain

Getting your products to their destination on time and in optimal condition is crucial. We offer logistics and shipping solutions to streamline the process, reduce costs, and minimize transit times. Whether your products are destined for local or global markets, we have the expertise to ensure safe and efficient transportation.

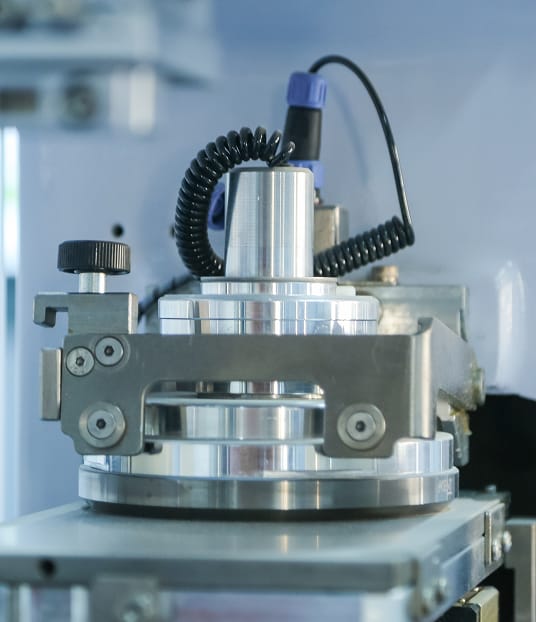

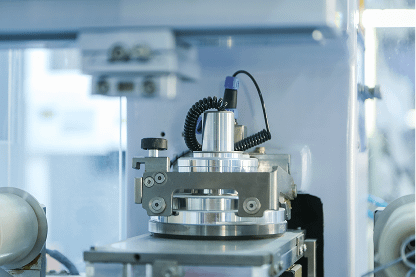

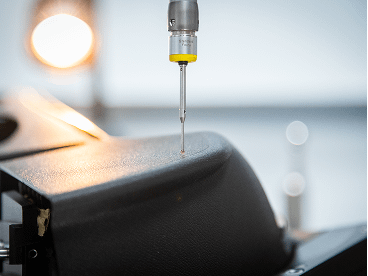

Quality Assurance and Testing

Quality assurance is at the core of our services. We conduct rigorous inspections and testing to ensure that your products meet your specifications and industry standards. Our testing capabilities encompass a wide range of criteria, from dimensional accuracy to material properties.

Full Project Lifecycle Support

Our commitment to delivering end-to-end solutions goes beyond injection molding. We offer a suite of related services to support your project, from component assembly and packaging to quality assurance and logistics. Our integrated approach streamlines your supply chain, enhances cost control, and ensures hassle-free project management.

Post-Molding Value Additions

FEATURES

Workbenches and jigs for repeatable tasks

Operator-assisted mechanical assembly

Optional automation for repetitive sub-assemblies

BENEFITS

Reduces time-to-market for complex products

Scalable setup for small or mid-size volumes

Ensures quality and dimensional control with human supervision

FEATURES

6-axis robotic sprayers with adjustable flow rates

Compatible with both solvent and water-based paints

Integrated curing tunnels for rapid drying

BENEFITS

Uniform paint thickness and color accuracy

Faster production vs. manual coating

Eliminates exposure risk for operators

FEATURES

Atmospheric plasma jet systems

Cell-integrated or inline configurations

Programmable surface energy targeting

BENEFITS

Reliable bonding on low-energy polymers (PP, PE)

Clean, solvent-free, eco-compliant process

Boosts coating, printing, or labeling durability

Applications

Where and how our post-molding services make a difference

- Consumer Electronics

- Appliances & White Goods

- Automotive Trim & Controls

- Industrial Components