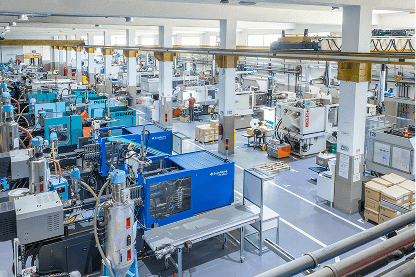

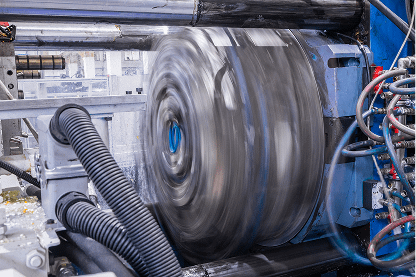

Technological Powerhouse

Our injection molding machines are at the forefront of technology. They are equipped with advanced features such as servo-driven systems, precision control, and high-speed capabilities. This technology ensures that every molded part meets the tightest tolerances and quality standards.

Wide Span of Clamping Force

We take pride in our diverse range of injection molding machines, each equipped with a specific clamping force tailored to meet the unique requirements of your projects. Our extensive clamping force capabilities, spanning from 50 tons to a robust 850 tons, allow us to provide you with a precise and comprehensive manufacturing solution.

Materials Matter

The selection of the right plastic material is paramount in injection molding. A wide range of thermoplastics, thermosetting plastics, and elastomers are available, each with unique properties. Material selection is influenced by factors such as strength, flexibility, chemical resistance, and environmental considerations. Understanding material properties is crucial for achieving the desired performance and aesthetics of the final product

Bi-Injection Molding

Bi-injection molding, also known as 2K molding, is a groundbreaking technique that allows for the injection of two different materials or colors into a single mold, producing a two-color or two-material component. This technology opens up a world of creative and functional possibilities. Often used for creating intricate designs, enhancing aesthetics, and combining materials with varying properties, such as soft & hard plastics.

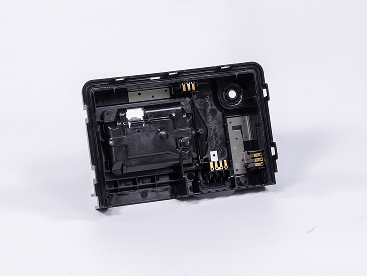

Overmolding & Insert Molding

Overmolding allows us to seamlessly encapsulate existing parts with a layer of precision-molded plastic, enhancing durability and ergonomics. Meanwhile, insert molding enables us to efficiently integrate non-plastic components, such as metal fasteners or electrical elements, into the heart of plastic parts.

360° Solution

From the initial concept and design phases to material selection, tooling development, precision molding, quality control, and even integrated tooling management – our commitment to excellence spans the entire manufacturing journey. Our 360° solution isn’t just about producing parts; it’s about forging lasting partnerships and delivering unparalleled results.

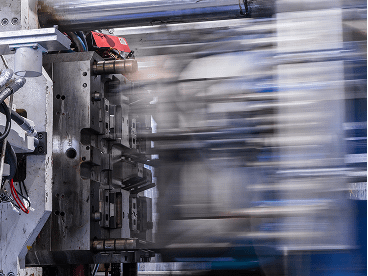

Technological Powerhouse

FEATURES

Dual machine types from 50T to 850T clamp force

Full digital control interface with real-time process monitoring

Quick-change mold systems compatible with both formats

BENEFITS

Enables precise, high-speed molding for complex geometries

Offers energy-efficient production with reduced cycle times

Facilitates part-specific optimization (high-pressure for thick parts, high-precision for aesthetics)

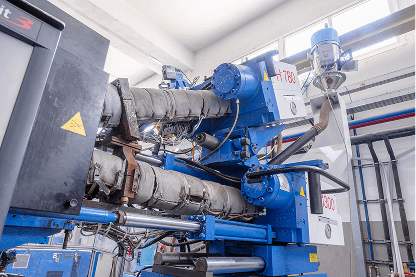

FEATURES

Press tonnage range from 50 to 850 tons

Equipped with servo-electric and hydraulic configurations

Centralized monitoring with automated cycle control

BENEFITS

Covers a wide variety of part sizes and weights

Flexible for short-run or high-volume production

Ensures stability, repeatability, and dimensional accuracy

FEATURES

Precise positioning systems for inserts (metal, electronics, etc.)

Compatible with hard-soft material combinations

Seamless integration into injection cycle

BENEFITS

Eliminates secondary assembly steps

Improves part durability and integrity

Enables hybrid or multifunctional components (e.g. grip + structure)

FEATURES

Dual-injection barrels with rotary mold systems

Multi-zone temperature and flow control

Integrated part transfer or core-back systems

BENEFITS

Enables aesthetic or functional combinations (color, texture, rigidity)

Consolidates multiple components into one part

Improves sealing, comfort, and mechanical performance

Thermoplastics We Process

Plasticum has extensive experience processing a wide variety of thermoplastics — from commodity resins to high-performance technical polymers. Each material is selected based on your product’s durability, chemical resistance, optical clarity, or flexibility needs.

- PP (Polypropylene)

- ABS (Acrylonitrile Butadiene Styrene)

- PA6 / PA66 (Polyamides)

- PC (Polycarbonate)

- POM (Polyoxymethylene)

- TPE / TPU (Elastomers)

- PC/ABS blends