Collaborative Design Workshops

Our engineers work closely with your team to brainstorm ideas, refine concepts, and ensure that every detail is considered. We encourage open dialogue, brainstorming, and the exploration of multiple design concepts to find the best solutions. Your input is central to the workshop process.

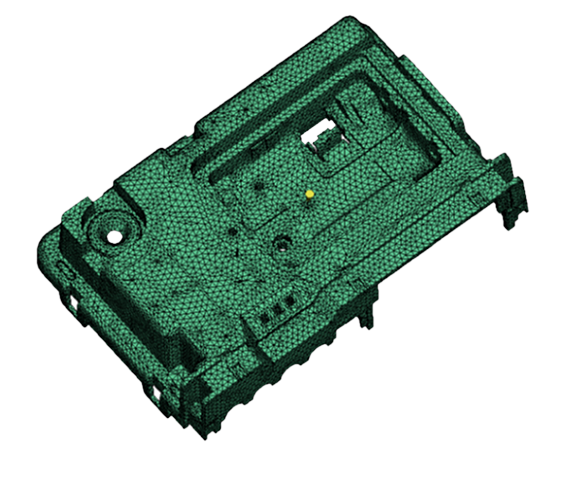

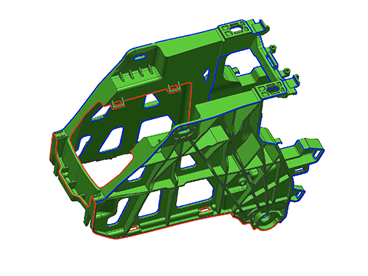

Design for Manufacturability (DFM)

We conduct thorough DFM assessments to identify potential issues and streamline the manufacturing process. By addressing these challenges early, we streamline the manufacturing process, resulting in faster turnaround times With DFM, we can quickly iterate and refine prototypes, reducing development time and allowing for faster product launches.

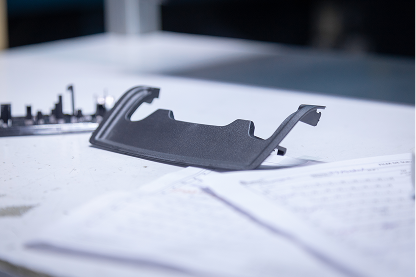

From Concepts to Prototypes

Prototypes are the bridge between concept and production. We create physical prototypes that allow you to see, touch, and test your design. This hands-on approach is invaluable for refining and validating your concept.

Iterative Improvement

Prototyping often leads to insights and improvements. We iterate and refine the design based on your feedback, ensuring that the final product aligns perfectly with your vision and objectives.

Material Selection Guidance

Choosing the right material is critical. We help you choose the most suitable materials for your project, considering factors such as strength, durability, cost, and environmental impact. Our commitment to sustainability means that we prioritize eco-friendly materials whenever possible.

Turn your vision into a manufacturable reality

Throughout the entire co-design and development journey, you can expect open communication, transparency, and a relentless pursuit of excellence. We’re not just in the business of making products; we’re in the business of bringing your visions to life.

COLD-ROLLED COIL PRODUCTS

BENEFITS

At Fabrik, we empower our customers to shape the future. Our Motor Steel is a specialized cold-rolled sheet product meticulously engineered to optimize the performance of electromagnetic core materials in electrical equipment components. These steels are designed to minimize energy losses, ensuring efficient utilization of electrical energy input into motors.

FEATURES

Our motor lamination sheets are meticulously cold-rolled below their recrystallization temperature, offering precise control over product shape, thickness, dimensions, and surface finish. We produce a variety of steel grades, with each grade primarily differentiated by its specific Core Loss requirement. These grades are provided in a semi-processed, unannealed state and must undergo annealing after punching the laminations to unlock their optimal magnetic properties.

BENEFITS

Home appliances are more than an essential part of our homes. They’re an essential part of life. VITRENEMEL Steel optimize the application of porcelain or vitreous enamel coatings and are manufactured with specialized properties that can achieve both good formability and enhanced aesthetics. Our steel products are cold rolled, producing a high quality finished surface to exceed our customers’ requirements.

FEATURES

Fabrik Steel produces three grades of steel that optimize the application of porcelain (or vitreous) enamel coatings that resist fish-scaling during the enameling process, resist carbon boil during enameling, and provide the sag resistance needed during the firing process.

All VITRENEMEL grades typically are furnished with a rough matte finish to improve adhesion of the enamel coating. The approximate surface roughness is 55 to 90 micro-inches. A rougher surface finish, 90 to 150 micro-inches, can be provided if required for a specific application.

The dimensional tolerances for VITRENEMEL Steel Sheet products are the same as those for Cold Rolled Steel Sheet as established by ASTM.

BENEFITS

Cold-rolled full hard unprocessed sheet by Fabrik Steel is the option to choose for applications that require very limited bending and/or roll-forming.Supplied directly from the cold-reduction mill without any annealing to soften the steel, our full hard sheet is highly work-hardened and exhibits a high resistance to denting, with only minimal ductility. The hardness is Rockwell B 84 minimum.

FEATURES

Since the product is supplied directly after cold rolling without further processing, our full hard cold-rolled unprocessed sheet is not subject to the same product standards that have been established for other cold-rolled sheet products.We provide it with a matte or smooth surface finish produced on the cold reduction mill.

Applications & Grades

They are a base material in applications that do not require any formability beyond minimal bending and/or roll-forming.

- Large and Small Electric Motors

- Generators

- Ballasts

- Transformers