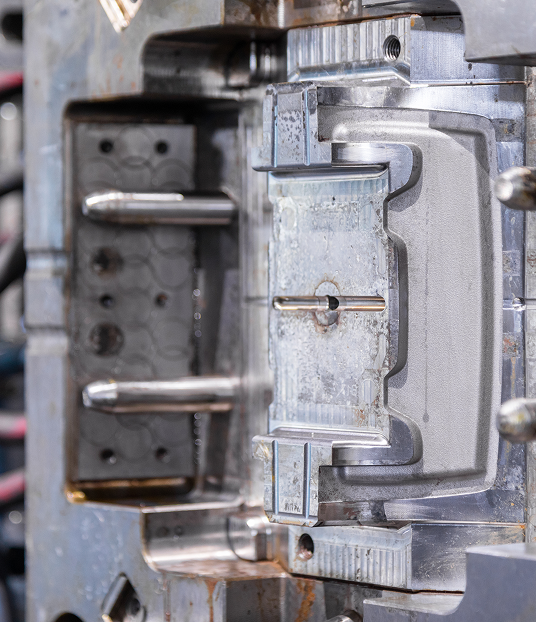

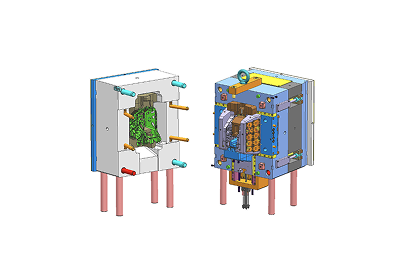

Custom Mold Design

Our team of experienced engineers meticulously designs molds that align with your project’s specifications. We consider factors such as part geometry, material flow, and cooling strategies to optimize mold performance.

Precision CNC Machining

Craftsmanship is at the heart of our mold manufacturing process. We utilize state-of-the-art CNC machining equipment and techniques to ensure the highest level of precision.

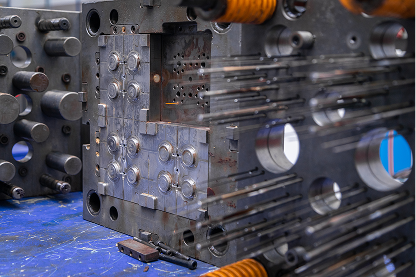

Multi-Cavity Molds

For projects that demand high-volume production, our multi-cavity molds offer an efficient solution. They allow for the simultaneous production of multiple parts, reducing cycle times and costs.

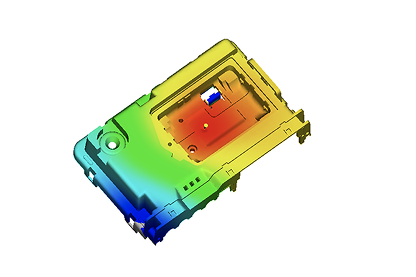

Mold Flow Analysis

Mold Flow Analysis allows us to detect issues like air traps, weld lines, or uneven filling early on. It helps optimize design and choose the right material by evaluating properties like viscosity and melt temperature for a smooth injection process.

Quality Assurance

Throughout the tooling manufacturing process, we maintain rigorous quality control measures. Our quality assurance team conducts thorough inspections and tests to ensure that every mold meets our exacting standards.

Maintenance and Refurbishment

We understand that tooling requires ongoing care to maintain peak performance. We offer maintenance and refurbishment services to extend the lifespan of your molds and reduce long-term costs.

COLD-ROLLED COIL PRODUCTS

BENEFITS

At Fabrik, we empower our customers to shape the future. Our Motor Steel is a specialized cold-rolled sheet product meticulously engineered to optimize the performance of electromagnetic core materials in electrical equipment components. These steels are designed to minimize energy losses, ensuring efficient utilization of electrical energy input into motors.

FEATURES

Our motor lamination sheets are meticulously cold-rolled below their recrystallization temperature, offering precise control over product shape, thickness, dimensions, and surface finish. We produce a variety of steel grades, with each grade primarily differentiated by its specific Core Loss requirement. These grades are provided in a semi-processed, unannealed state and must undergo annealing after punching the laminations to unlock their optimal magnetic properties.

BENEFITS

Home appliances are more than an essential part of our homes. They’re an essential part of life. VITRENEMEL Steel optimize the application of porcelain or vitreous enamel coatings and are manufactured with specialized properties that can achieve both good formability and enhanced aesthetics. Our steel products are cold rolled, producing a high quality finished surface to exceed our customers’ requirements.

FEATURES

Fabrik Steel produces three grades of steel that optimize the application of porcelain (or vitreous) enamel coatings that resist fish-scaling during the enameling process, resist carbon boil during enameling, and provide the sag resistance needed during the firing process.

All VITRENEMEL grades typically are furnished with a rough matte finish to improve adhesion of the enamel coating. The approximate surface roughness is 55 to 90 micro-inches. A rougher surface finish, 90 to 150 micro-inches, can be provided if required for a specific application.

The dimensional tolerances for VITRENEMEL Steel Sheet products are the same as those for Cold Rolled Steel Sheet as established by ASTM.

BENEFITS

Cold-rolled full hard unprocessed sheet by Fabrik Steel is the option to choose for applications that require very limited bending and/or roll-forming.Supplied directly from the cold-reduction mill without any annealing to soften the steel, our full hard sheet is highly work-hardened and exhibits a high resistance to denting, with only minimal ductility. The hardness is Rockwell B 84 minimum.

FEATURES

Since the product is supplied directly after cold rolling without further processing, our full hard cold-rolled unprocessed sheet is not subject to the same product standards that have been established for other cold-rolled sheet products.We provide it with a matte or smooth surface finish produced on the cold reduction mill.

Applications & Grades

They are a base material in applications that do not require any formability beyond minimal bending and/or roll-forming.

- Large and Small Electric Motors

- Generators

- Ballasts

- Transformers