Smart Molds, Everyday Use

The home appliances industry requires more than reliability — it demands smart, aesthetic, and production-efficient solutions that stand the test of time. At PLASTICUM, we support leading manufacturers with plastic components that meet thermal, structural, and functional performance under real-world usage. Whether it’s washing machines, ovens, coffee machines or smart kitchen interfaces, our ability to mold complex geometries with consistent quality makes us a key contributor to appliance performance and brand differentiation. We continuously adapt our processes to support cost optimization, design innovation, and time-to-market imperatives.

DEDICATED TO INNOVATION

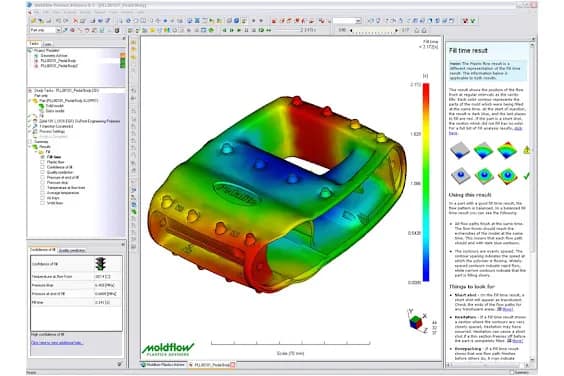

At Plasticum, innovation is not an afterthought — it’s engineered into every stage of our process. Across all industries we serve and every capability we master, our teams apply advanced technical know-how, cutting-edge tools, and a proactive mindset to help clients meet complex design, cost, and sustainability challenges. From high-performance engineering polymers to optimized mold designs and precision injection technologies, our aim is to co-create smarter, lighter, more efficient solutions. We partner early and think long-term — because true innovation isn’t just about making things — it’s about making things better, faster, and cleaner.

High-Precision Housings

We produce injection-molded casings and structural parts for washing machines, dryers, ovens, and refrigerators. Our process ensures stability, chemical resistance, and cost-efficiency across large volumes.

Thermal & Electrical Insulation

For heating and cooling systems, we mold high-temperature resistant parts with excellent insulation properties. These components meet strict safety norms and ensure energy efficiency.

Water Handling Systems

We develop watertight, pressure-resistant plastic parts for pumps, valves, and flow-control systems in dishwashers and laundry machines. Quality assurance ensures leak-free operation and long lifecycle.

Fast Product Launches

With rapid tooling and DFM (Design for Manufacturability) support, we help brands reduce time-to-market. Our integrated workflow ensures seamless transition from prototype to mass production.

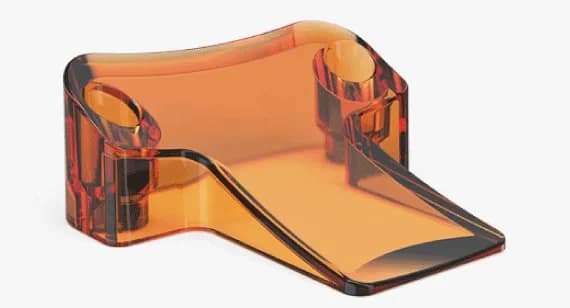

Customization at Scale

Appliance brands rely on design flexibility and high visual quality. We offer aesthetic customization—colors, textures, surface treatments—without compromising dimensional repeatability.

Long-Term Partnerships

Trusted by leading white goods manufacturers in Europe and North Africa, PLASTICUM ensures robust production planning, just-in-time delivery, and full traceability.