Molding Connectivity

From insulation to enclosures, the electrical sector relies heavily on durable, high-precision molded components. PLASTICUM manufactures technical plastic parts that enable safe, scalable electrical installations across residential, industrial, and energy infrastructure applications. We help our partners meet regulatory and safety standards with reliable materials, dimensional accuracy, and traceable quality workflows. As power distribution and control technologies evolve, we remain committed to supporting innovation through material know-how and manufacturing agility.

DEDICATED TO INNOVATION

At Plasticum, innovation is not an afterthought — it’s engineered into every stage of our process. Across all industries we serve and every capability we master, our teams apply advanced technical know-how, cutting-edge tools, and a proactive mindset to help clients meet complex design, cost, and sustainability challenges. From high-performance engineering polymers to optimized mold designs and precision injection technologies, our aim is to co-create smarter, lighter, more efficient solutions. We partner early and think long-term — because true innovation isn’t just about making things — it’s about making things better, faster, and cleaner.

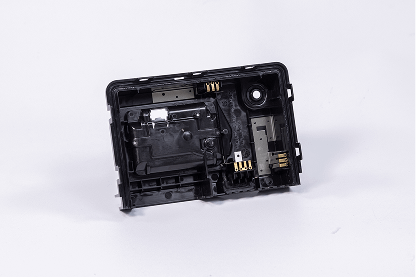

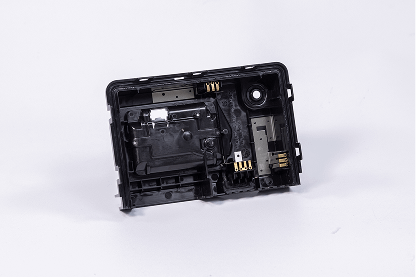

Connectors & Insulators

We mold highly precise parts for connectors, clips, sockets, and insulating barriers. These components are essential in ensuring electrical safety and conductivity.

Precision for Power

We produce injection-molded components that support the integrity of electrical systems — from enclosures to structural parts. Designed for precision and durability, our solutions meet the evolving demands of energy distribution, automation, and connectivity

Low Shrinkage, High Stability

Electrical components demand exact dimensions. We use advanced molds and resins to guarantee consistent form, fit, and function across millions of cycles.

High Cavity Molds

We produce high-volume parts like terminal blocks and wire holders using high-cavity molds for efficiency, repeatability, and cost control.

Full Traceability

For all electrical parts, we ensure backward traceability of batches, materials, and process parameters—essential for safety audits and certifications.

Collaborative Co-Engineering

We collaborate with global OEMs to design injection-friendly parts that meet electric current handling needs while optimizing for tooling and production.